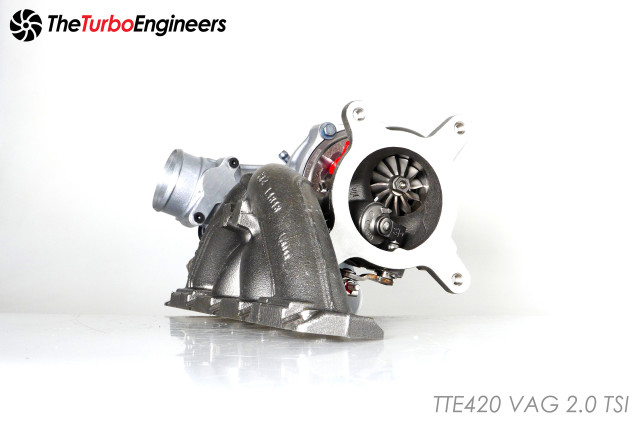

The Turbo Engineers - TTE420 Hybrid 2.0TSI Turbo Charger

TTE420 Upgrade Performance Turbocharger VAG 2.0 TFSI (EA113)

Please note: These are a special order with a dispatch time of 4-6 weeks from date of order.

The formula to making a TTE420 starts with a much larger 2871X TTE billet compressor wheel, chosen because is highly efficient, new generation type with very thin blades, creating an extremely high flow for comparative size, giving a compressor map that's very wide. The Re-Profiled compressor cover is machined to an optimised tolerance to ensure maximum compressor efficiency is given. Also, the intake pipe is ported to give a smooth transition for the incoming air flow. We also fit our TTE CNC K04 silencer delete, we modify the turbo discharge silencer, removing the baffle internals and fitting a new straight through section, removing any restriction and its function as a noise cancelling device, so improving the flow and enhancing the sound.

A key part to driving the large 2871X compressor and in turn making this unit produce the huge power advantage overstock and also our 400 upgrade hybrid, is machining and fitting a far larger BorgWarner K16 curved clipped turbine and shaft, while still keeping the k04 core, this is not so easy to do. This K16 turbine gives much lower back pressure and keeps EGT lower compared to stock K04 turbine or clipped stock.

The clipping of the K16 turbine. Clipping reduces blade area thus increasing gas flow and so reducing backpressure and lowering exhaust gas temperatures, allowing safer higher boost levels. This process also gives a secondary advantage of removing some material, lightening the turbine thus reducing the rotational mass improving moment of inertia. Dyno's have shown a little loss in response vs stock K04 yet huge gains in power and torque.

Special TTE developed in house 360 deg high-performance motorsport journal bearing system is fitted. Durable at high loads with no loss in transient response.

The actuator used is uprated sprung OE unit, fitted with our reinforced clamps for trouble-free operation. This also can also be modified to customer needs and specifications.

Equilibrium

Precisely balancing our turbochargers is a key critical factor to become a TTE upgrade unit as longevity and performance are paramount. Good balance improves acoustics also. Subsequent great care is taken with all TTE turbochargers to achieving our balance standards. Firstly parts are balanced at slow speeds up to 2800RPM in multiple planes using our single parts machine, then components are assembled and then the CHRA are dynamically balanced, but this time depending on application at up to 250,000 RPM in multiple planes using our in-house VSR machine to acquire the ultimate equilibrium, to a standard far higher than OEM. Each turbocharger is supplied with serial numbered balance test result document.

Features

Do we ship abroad ?

Yes we do, to almost anywhere in the world though remember the postage is often high when shipping anything bulky. Most bulky items we export will go by DHL so you can track the package online and could reach America within 48 hours providing its in stock !

However there are a few countries we do not ship to, some of these include: Israel, Thailand, Malaysia, Indonesia, Russia, Nigeria, Macedonia, Syria, Ukraine, Lebanon.

Why is postage on bulky items to some countries expensive compared to some other companies ?

For both yours and our safety we use well known courier Parcel Force and DHL for shipping, then we know exactly where it is in the world at any time and we know its going to arrive safely. Shipping small items can be cheap, but items such as bodykits are expensive to ship - we have a very small margin on the postage fees merely to cover packaging. We can now ship using standard post on some items, however using all methods you may incur import charges when you receive the goods for which we cant be responsible for.

Local Customs and Duty Charges:

For all customers outside of the UK, prices now displayed in cart once you enter your address will have 20% UK VAT Tax removed, however you will likely have to pay some form of Duties / VAT prior to delivery of your goods.

If you are unsure of charges we recommend you should contact your local authorities ahead of placing your order.

Availability:

Not everything on our website is in stock, if you need a part desperately please contact us first to confirm availability before placing your order

How do I place an order if I live within the UK ?

You can either order here in our online shop or you can phone us or email us, using the following number/address are below.

Phone: 0161 776 0777 (Option 2)

email: sales@awesomegti.com

How do I place an order if I live outside the UK ?

You can order online or by phoning or emailing us.

email: sales@awesomegti.com

Returns Procedure:

- Before returning any goods please read all our terms and conditions.

- Awesome must be informed by e-mail or telephone on 0044 (0) 161 776 0777 (option 3) of any items that you wish to return for credit or exchange within 14 calendar days commencing the day of delivery. A member of staff will provide you with a Returns Notice Number.

- Please also ensure that you include a copy of your invoice when shipping any items back to us as well as your Returns Notice Number.

- If an item is sent back to us without a Returns Notice Number; a refund will not be given.

- No parts that have been used, fitted or installed will be accepted for Credit or Refund.

- We will not under any circumstances pay any VAT/Import Duties on returns, If we are requested to do so your return will be rejected/abandoned.

- Returns Notice Numbers are valid for 1 calendar month, if the goods are not returned within that period, the returns notice number will be cleared and if you wish to return the goods this will be treated as a new request and may be rejected.

For orders that have been supplied correctly & assuming goods are in re-saleable condition:

-Within 14 days from the day of delivery - Goods can be returned for any reason for a full refund of goods and outgoing delivery charge.

-We do not cover returns postage back to us

-After 14 days from the day of delivery - Goods can be returned but with a 20% handling charge. The initial delivery charge & return delivery charges will NOT be refunded.

-After 28 days from the day of delivery – Goods are not accepted back for refund.

For orders that have been supplied incorrectly & assuming goods are in re-saleable condition:

-Within 28 days from the day of delivery – Goods can be accepted back for full refund, refund for initial shipping and refund for return shipping.

-If goods are not in re-saleable condition e.g fitted/test fitted, original packaging not present, covered in grease/lube etc, supplied correctly or incorrectly we will not accept for a refund.

At our discretion, we may drop ship your order direct from a UK supplier. If we arrange to drop ship an item it will be arranged internally, you only pay the price agreed in advance.

When shipped by courier a mandatory signature is required upon delivery